IF YOU ARE A NEW ZEALAND ARCHITECT OR SPECIFIER, HERE IS WHAT YOU NEED TO KNOW:

As the designer or architect of public spaces such as educational institutions, aged care facilities, medical centres, or hospitals, acceptable Solution D1/AS1 of the New Zealand Building Code states that adequate slip resistance is required on all public access routes, including access into and within buildings.

One of the strictest surface requirements are those involved in the design of hospitals so this can be set as the highest benchmark. The same or similar rules on slip-resistant surfaces can be applied to any space used by the public. Flooring should be anti-slip, have a high resistance to the wear of foot traffic and equipment, ideally be stain and scratch-resistant, easy-to-clean, and non-flammable.

Most porcelain tiles meet slip standards for safety-compliant spaces. Aside from meeting such requirements, tile is a durable, strong surface, and the most eco-friendly flooring choice available being VOC-free (unlike other flooring surfaces that contain harmful contaminants such as petroleum).

Avoiding Personal Injury claims

To prevent floor slips and personal injury claims, employers, architects, and managers involved in the decisions of flooring are required to source suitable, fit-for-purpose products that are accompanied by technical specifications detailing slip resistance.

The principal objective for D1: Access routes in our Building Code is to safeguard people from injury during movement into, within, and out of buildings. The specific clause relevant to slip resistance in D1 is 1.3.3(d) and relates to access routes having adequate slip resistance walking surfaces under all conditions of normal use.

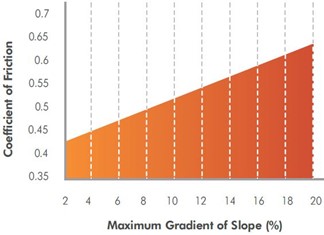

An acceptable solution follows (D1/AS1) and indicates that for level access routes to which the public has access, including level accessible routes, shall have a mean coefficient of friction μ, of not less than 0.4 when tested in accordance with AS/NZS 3661.1 ...In addition, requirements for ramps and stairways are required to be consistent with the Table 2 of D1/AS1.

To determine what the minimum required slip resistance value is for a ramp or sloped surface (gradient not less than 2%), the following equation can be used:

μm = 100μ + M / 100 - Mμ

Where:

- μm = coefficient of friction required for a sloped surface

- μ = coefficient of friction obtained on a horizontal surface

- M = maximum gradient of slope in percent.

Overall, compliance with the slip resistance performance of NZBC D1.3.3(d) may be verified by confirming that the walking surface under the expected conditions of use has a coefficient of friction (μ) of no less than:

μ = 0.4 + 0.0125S where S is the slope of the walking surface expressed as a percentage.

In regards to NZBC D1.3.3(d), the required coefficient of friction value is not based on wet or dry conditions. So, if for a level surface you are required to have a slip-resistant coating that meets the NZBC in wet conditions, the coefficient of friction values doesn't change, but your surface coating may, in order to provide a wet slip resistance rating of no less than 0.4.

Using the AS/NZS 3661.1 standard, you can elect to either test for dry slip or wet slip. It is generally expected that surfaces that have been shown to comply with the wet requirement would also comply with the dry requirement.

Slip tests explained:

1. The 'R' Rating (Ramp test) - A floor test is conducted on a ramp set at varying inclined angles, the ramp testing providing different results as the ramp gets steeper; the steeper the ramp can be raised without heel slip then the better (higher) the Ramp Test/'R' Rating results range from R9 or least Floor Slip Resistance [Not R1] to R13, the most Slip Resistance.

Indicative SRV Range:

|

|

SRV Range |

|

R9 |

< 34 |

|

R10 |

34~44 |

|

R11 |

45~54 |

|

R12 |

> 54 |

2. The Coefficient of Friction (CoF) - gives true slip testing figures. The Floor Slip Test Coefficient of Friction is determined using a Pendulum Test, usually carried out by independent bodies in NZ.

When the slope increases, there is a requirement for an increased coefficient of friction (COF) test result. For example, a surface of a slope of 8% would require a COF of 0.5.

To fully understand these tests and how they relate to your project,

View or Download our comprehensive brochure on SLIP-RESISTANT surfaces by CLICKING HERE >>>

or speak with one of our Commercial Representatives for Guidance. CLICK HERE for details >>>

References: WHY TILE Commercial Guide >>> EBOSS.co.nz >>>